Difference between revisions of ".17 Incinerator"

| Line 20: | Line 20: | ||

Several annealing steps (at least three) are taken during this process. A small lathe is then used to clean up imperfections on the neck and shoulder. Finally for the neck, he reams the inside diameter and trims to length. Weighman now "sanitizes" the headstamp by turning them in his lathe, and etches his own. And finally, he seats the bullet into the case and polishes. | Several annealing steps (at least three) are taken during this process. A small lathe is then used to clean up imperfections on the neck and shoulder. Finally for the neck, he reams the inside diameter and trims to length. Weighman now "sanitizes" the headstamp by turning them in his lathe, and etches his own. And finally, he seats the bullet into the case and polishes. | ||

| + | |||

| + | == Other Articles == | ||

| + | |||

| + | * [[P.O. Ackley]] | ||

| + | * [[.22 Eargesplitten Loudenboomer]] | ||

| + | * [[.50 BMG]] | ||

| + | * [[Cartridges of the World]] | ||

[[Category:Wildcat Cartridges]] | [[Category:Wildcat Cartridges]] | ||

Revision as of 11:09, 24 May 2023

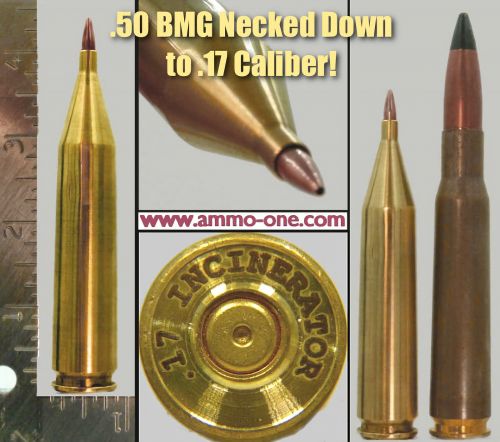

The .17 Incinerator is a novelty Wildcat Cartridge created by necking down a .50 BMG case all the way down to .17 caliber (.177?) - a process which takes many steps. This article will cover that process in a section below. We'll also attempt to uncover who really came up with the .17 Incinerator, as this seems to be up for debate on the web.

Some claim it was created by "Kent Wilson" of Ammo-One, however this is cited in an article by AccurateShooter.com. The problem is that this is an April Fool's article, and gives what appears to be completely made-up ballistics (and prairie dog destruction) - for comedy's sake, or perhaps the gullible, or both? We could find no record of a firearm ever produced for the cartridge, even as a novelty firearm not intended to fire it. One thread at CartridgeCollectors forum showed off an overall similar cartridge, though with a different shoulder angle (possibly the ".17 Incinerator Improved" based on other pictures on the web. The user said "This is a total fantasy created by someone who was testing the outer limits of rifle barrel patience and pressure tolerance. According to Keith, the rifle blew up after the 3rd round and all experimentation stopped. The body is of a .50 cal round." Whether that specific information is accurate, is hard to say.

On the other hand, Frank Barnes' Cartridges of the World claims it was created as a completely inert novelty cartridge, by a machinist named Zachary Weighman. He also has been credited with creating the ".22 Earsplittingloudenboomer", a .50 BMG cartridge necked down to accept a .224 caliber projectile. That is also an inert novelty cartridge, but it should not be confused with the .22 Eargesplitten Loudenboomer, an actual working creation of P.O. Ackley in order to break the 5,000 feet per second velocity mark with a conventional firearm. That experiment was actually based on the .378 Weatherby Magnum case, necked down to .224 caliber. While it's also fairly comical-looking, it was actually live tested.

Origins

It isn't entirely clear who originally created the .17 Incinerator. For example, Frank Barnes' Cartridges of the World (14th Edition) claims that it was first produced by a machinist named Zachary Weighman. His version is inert, and contains no powder. The primer is simply from the original spent .50 BMG round. At the time, he sold them as a novelty for $20 at gun shows and it is noted that the finished piece has no cracks on the neck of the case.

According to Zachary Weighman, "I started making these up for friends of mine, after seeing a drawing of ‘Dingbat cartridges’—drawings of mythical cartridges. I thought they were really cool, so I started trying to figure out how to make them. As you can see, I did get it figured out.”

The Process

As per his story in Frank Barnes' Cartridges of the World (14th Edition and on), Zachary Weighman says, "... the process takes many sizing and annealing steps and some lathe work to machine." Weighman uses his small home mill and lathe setup. He made a die to hold inserts for necking down .50 BMG cases, with each having a smaller diameter hole in it. After 13 steps, the case has arrived at the proper size.

Several annealing steps (at least three) are taken during this process. A small lathe is then used to clean up imperfections on the neck and shoulder. Finally for the neck, he reams the inside diameter and trims to length. Weighman now "sanitizes" the headstamp by turning them in his lathe, and etches his own. And finally, he seats the bullet into the case and polishes.